The United Arab Emirates (UAE), globally recognized for its massive development and strategic economic diversification away from oil, is fast becoming a pivotal hub in the global zinc scrap market. As a critical non-ferrous metal, zinc’s role in galvanization (corrosion protection for steel) and die-casting makes its recycling indispensable, particularly in the construction and manufacturing-heavy economies of the Middle East and Asia. The nation’s commitment to a circular economy has transformed zinc scrap from mere industrial waste into a highly valued, tradable commodity, fueling both domestic industry and a significant export sector.

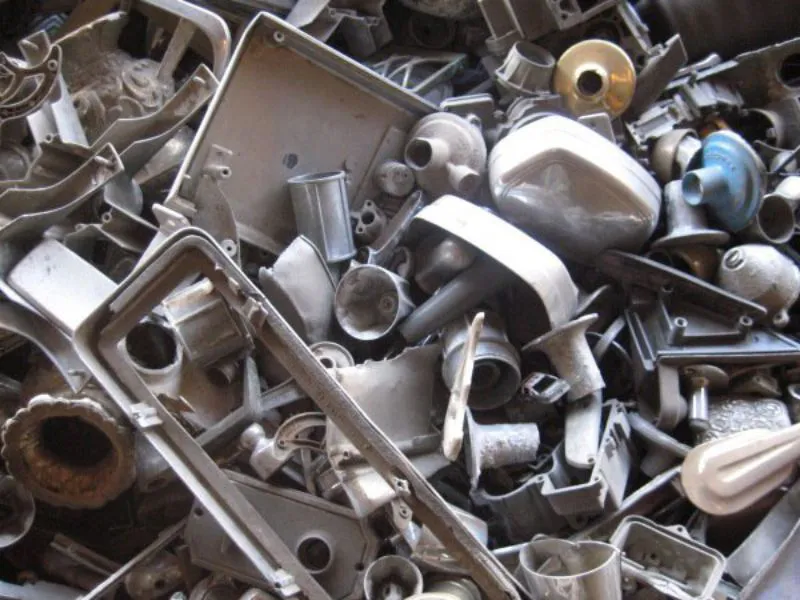

The UAE’s zinc market exhibits a dynamic flow characterized by substantial domestic consumption, buoyant exports, and considerable imports to meet processing demand. The country’s demand for zinc stems primarily from its vast infrastructure projects, where galvanized steel is essential for long-term durability against the harsh climate. This constant industrial activity generates a steady stream of end-of-life products and manufacturing by-products, such as Zinc Diecast Scrap and Zinc Dross, which form the primary sources of domestic supply.

However, the UAE’s recycling industry, leveraging its strategic port locations in Dubai and Sharjah, functions as a major regional processing and trading center. The country imports large volumes of zinc scrap to consolidate, sort, and process materials for re-export. Major destinations for UAE’s zinc exports often include industrialized nations in Asia, like China, Oman, and Malaysia, which have large smelting and manufacturing sectors requiring secondary raw materials. The ability of UAE-based traders to efficiently process and re-export zinc and its derivatives, such as zinc ash and zinc dust, highlights its significance in the international supply chain.

The zinc scrap lifecycle in the UAE is handled by a sophisticated network of metal trading and recycling firms. Companies like Hope Star General Trading, ClearEarth Recycling, PGI Group, and Nicro Metals Waste Trading are among the notable players. These businesses specialize in the procurement, sorting, and processing of ferrous and non-ferrous metals, with zinc being a core non-ferrous offering.

The process of recycling zinc scrap typically involves:

This technological adoption, combined with the presence of multiple industrial free zones like Jebel Ali Free Zone (JAFZA) and Umm Al Quwain Free Trade Zone (UAQ FTZ), creates an efficient ecosystem that minimizes overheads and maximizes the speed of trade, reinforcing the UAE’s competitive edge.